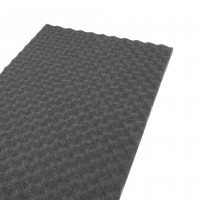

Comfortmat G4 anti-vibration material

More about the product

Comfortmat G4 anti-vibration material

The advanced Comfortmat anti-vibration material of the Gold model series, which underwent a complete innovation in 2021. At first glance, the new print of the material, which now corresponds to the current design of Comfortmat products, catches the eye. However, the improvement did not stop only at the design and the color, which is now even more golden. Innovations can also be found in the composition of the material, namely its higher efficiency and adhesion. The Gold model series with its unique G-Formula composition continues the basic Standard series and provides input materials with unique properties that premium materials from competing manufacturers offer. Due to their composition, the materials of the Gold series have a 300% higher adhesion to metal material than standard materials, and at the same time their weight has also been reduced. Thanks to the use of specially modified elastomer, the cushioning material Comfortmat G4 has a high coefficient of mechanical losses, excels in excellent adhesion to metal, is resistant to water, moisture, oils and extreme temperatures, has anti-corrosion properties and retains the same properties in winter and summer..jpg)

Unique technology of the Gold model series

Comfortmat G4 has a special foil, the production process of which uses HotAL II double heat treatment technology. This guarantees increased rigidity of the film while maintaining excellent flexibility during work. The new inFliz technology for simple application of the butyl mixture on aluminum foil allows the complete absence of air between the layers, and thanks to a more even distribution over the entire surface, it significantly improves the properties of the materials. Thanks to the advanced technology of mixing the components of the GoldMix rubber sealant, it was possible to use new components that previously could not be used in classic production. It was possible to improve all important indicators, which mainly results in weight reduction, more convenient installation and significantly higher adhesion to metal. Printing on aluminum foil with a thickness of 100 microns contributes to its design for easy cutting and quick installation. The material is available in thicknesses of 2.3 mm, 3 mm and 4 mm.

The main properties of the anti-vibration material Comfortmat G4

- Anti-vibration material with a thickness of 4 mm from the Gold model series.

- Up to 300% more adhesion to metal than standard anti-vibration materials.

- Reduced weight thanks to the advanced technology of mixing the components of the butyl layer.

- Resistance to water, moisture, oils and anti-corrosion properties.

- The same properties in winter and summer thanks to high resistance to extreme temperatures.

- HotAL II technology for increased rigidity of the aluminum foil while maintaining high flexibility during application.

- Simple installation on all types of surfaces without the need for heating.

- The new inFliz technology enables the complete absence of air between the layers of butyl and aluminum foil.

- Unique EarthPrint design in gold-black color with special mesh for easy cutting.

Technical parameters of the Comfortmat G4 material

- Thickness: 4 mm

- Size: 700 x 500 mm

- Weight: 2.15 Kg (6.14 kg / m²)

- Acoustic Loss Factor (MLF): 0.45

- Adhesion: 14 to 16 N/cm

- Stamping: Ingot-M 6 x 12 mm

- Color: gold-black

- Price for 1 piece

Where to apply the Comfortmat G4 material

You can apply the Comfortmat Gold G4 anti-vibration material almost anywhere where you need to reduce vibrations and resonances. However, due to the thickness of 4 mm and the high acoustic loss factor, the material is particularly suitable for areas with a very high vibration load. A suitable area of use is especially the floor, engine partition and front and rear wheel arches. In our article " how to choose an anti-vibration material ", you will learn all other information about anti-vibration materials, their use, and the right choice. A thickness of 4 mm is unnecessarily thick for other surfaces of the vehicle. If you are not sure what materials and in what quantity to use for vehicle soundproofing, use our soundproofing configurator . The most common uses of the Comfortmat G4 anti-vibration material:- Floor

- The bottom of the trunk

- Front metal wheel arches

- Rear metal wheel arches

- Engine bulkhead

- Central tunnel

- Torpedo

About Comfortmat cushioning materials

The Comformat company has been operating on the market since 2010 and during that time has quickly established itself as a leading global manufacturer of anti-vibration and sound insulation materials. Comfortmat brought new technologies to the automotive industry enabling maximum efficiency, lower material weight, constant efficiency even in extreme temperatures and, last but not least, very easy application. In recent years, Comfortmat has been leading the way in the field of vehicle soundproofing and regularly brings to the market materials with record efficiency and excellent properties that have not been possible to achieve until now. All this is only possible through many years of research in the Comfortmat laboratories, the highest quality control at every stage of production, the modernization of production machines with the involvement of the world's leading experts in the automation of production lines and the creation of a research center equipped with the most modern equipment. Comfortmat's highly qualified experts have extensive scientific and manufacturing experience, regularly perform the necessary physical and mechanical tests, and have expertise in the vibroacoustic properties of cars. Thanks to this, Comfortmat products can meet the most demanding requirements of the current automotive market.| Catalog number | COM G4 |

| Brand | Comfortmat |