Sound insulation material Comfortmat Fusion XL

More about the product

- Use our consulting room

- You can return the goods to us within 14 days

- Try the product at our store

Sound insulation material Comfortmat Fusion

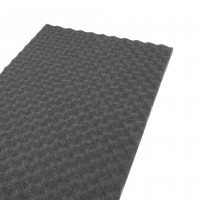

Comfortmat Fusion is a highly effective sound and heat insulating material, the biggest asset of which is its very low weight and at the same time excellent ability to absorb noise. The modern material launched in 2019 is made of highly effective acoustic foam AcoFoam based on a mixture of synthetic rubbers. Comfortmat Fusion is a variant of the soundproofing material Comfortmat Vision , the difference is mainly in its thickness. While the Vision is 6mm thick, the Fusion is only 3mm. So it fits wherever the overall thickness of the materials may be a problem for some cars. Fusion is also extremely light with a specific weight of just 440g per 1m². It was developed especially for installations where the main task is not to increase the weight of the car too much and at the same time to dampen it very effectively. The material is very flexible and can be applied even to significantly embossed surfaces. Thanks to its polymer structure, Comfortmat Fusion combines excellent performance in a wide temperature range with high biological resistance. An important part of the material is also the latest generation of modern assembly adhesive sealant developed for the 2018/2019 season, which guarantees the same adhesive effect at temperatures from -50 to +150 degrees. It can therefore be guaranteed that Fusion will never peel off on its own even on very curved and embossed surfaces. Of course, Fusion is completely waterproof, does not absorb moisture, does not rot and does not decompose.

Main features of the Comfortmat Fusion material

- Sound insulation material intended for soundproofing almost all surfaces in the vehicle.

- The lightest of all Comfortmat materials - ideal for installations where it is not advisable to increase the weight of the car too much.

- High level of sound insulation up to 10 dB while maintaining extremely low thickness and weight.

- 100% resistant to water, oils and moisture, does not rot, absorb moisture and does not decompose.

- Highly adhesive self-adhesive layer, thanks to which the material does not come off on its own even under water.

- Resistance to extreme temperatures - the same adhesive effect at temperatures from -50 to +150 degrees.

- Convenient installation even on very curved and relief surfaces thanks to the high flexibility of the material.

- Reduced thickness of 3 mm for areas where it is necessary to maintain a smaller thickness of materials.

Technical parameters of the Comfortmat Vision material

- Thickness: 3 mm

- Size: 700 x 1000 mm

- Isolation: up to 10 dB

- Weight: 332 g

- Specific weight: 0.440 kg / m²

- Adhesion: 6 to 8 N/cm

- Price for 1 piece

.jpg)

Where to apply the cushioning material Comfortmat Fusion

Comfortmat Fusion finds its most frequent use especially in areas where the overall thickness of the materials could be a problem for some vehicles. As a rule, this is the bottom of the luggage compartment, the area under the rear seats, or the rear wheel arches, if a third layer of soundproofing is also applied. We often apply it to the floor of some commercial vehicles, where there is no room for a thicker material. Fusion is also suitable for installations where you don't want to increase the weight of the car too much, but at the same time effectively dampen it. It is applied as a second layer to an anti-vibration material (for example Comfortmat D2 ), which prevents vibrations and resonances. If you are not sure about choosing a suitable material, we recommend using our soundproofing configurator , which offers suitable materials and the number of pieces according to the type of car. The most common uses of Comfortmat Fusion cushioning material:

- The bottom of the luggage compartment

- Space under the rear seats

- Floor

- Rear wheel arches

- Plastic wheel arches

- Hood

About Comfortmat cushioning materials

The Comformat company has been operating on the market since 2010 and during that time has quickly established itself as a leading global manufacturer of anti-vibration and sound insulation materials. Comfortmat brought new technologies to the automotive industry enabling maximum efficiency, lower material weight, constant efficiency even in extreme temperatures and, last but not least, very easy application. In recent years, Comfortmat has been leading the way in the field of vehicle soundproofing and regularly brings to the market materials with record efficiency and excellent properties that have not been possible to achieve until now. All this is only possible through many years of research in the Comfortmat laboratories, the highest quality control at every stage of production, the modernization of production machines with the involvement of the world's leading experts in the automation of production lines and the creation of a research center equipped with the most modern equipment. Comfortmat's highly qualified experts have extensive scientific and manufacturing experience, regularly perform the necessary physical and mechanical tests, and have expertise in the vibroacoustic properties of cars. Thanks to this, Comfortmat products can meet the most demanding requirements of the current automotive market.

| Catalog number | COM FUSION XL |

| Brand | Comfortmat |

| Oversized shipment | Yes, |

| Material type | Sound insulating |

| Thickness | mm |

| Dimension | 1000 x 700 mm |

| Sound isolation | 10 dB |

| Anti-noise membrane | No |

| Weight 1 piece | 332 g |

| Basis weight | 0.440 Kg / m² |

| Adhesion | 6 to 8 N/cm |

| Color | Red with white print |

| Price for | 1 piece |

| Layer order | 2nd layer |